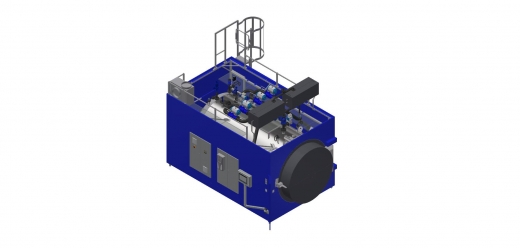

Autoclave the next generation

The fully automatic steam autoclaves are offered by MK Technology in five different standard sizes, special

sizes can also be provided on demand. Depending on the type and connected load, the single heating time

is only 30 minutes, and the pressure compensation is less than 3 seconds. The fast pressure generation up

to 10 bar in the process vessel guarantees a gentle dewaxing of the shell - the surface will melt before the

wax is able to expand.

Thanks to the SPS control and the touch screen, the handling of the system is uncomplicated and largely

automated, which applies to all other MK systems, as well. The mould trolley with the Quick-in / Quick- out

system allows the quick and easy feeding of the autoclave as well as a vibration- and shock-free mould

handling. All data which are important for the process are recorded up to four times per second and stored

in an external or internal data base. This allows a perfect documentation of the whole dewaxing process for

any cycle, which is very helpful to the end user. Due to the fact that all consumption values and performance

data are recorded, maintenance and servicing may be adjusted optimally.

The whole autoclave, from the vessel to the components, is “Made in Germany”.

Product Video

Technical Data

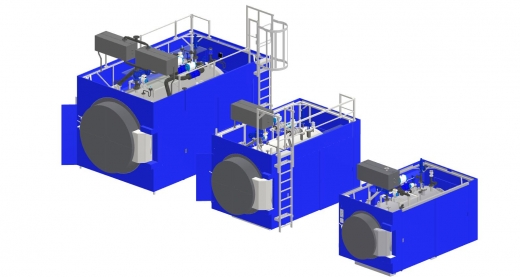

Set-up options

Manifacture in Grafschaft

Modern investment casting processes are based on so-called steam autoclaves in order to remove the wax quickly and gently. Only the highly energized saturated steam with a temperature of 178°C guarantees the melting of the wax at the surface before it can expand and damage the mould.

When designing the MK autoclaves, highest priority was therefore set on a quick and regular steam injection – the pressure of 8 bar is reached within 3 to 4 seconds, depending on the size of the autoclave.

A clear separation of wax and condensed water with drainage into closed collecting systems is part of the equipment as well as an automatic positioning aid for the mould trolley.

The systems are manufactured in accordance with the respective guidelines of the country of destination or ASME standards, they are certified by TÜV and have a pressurized door with 4-fold protection. Control is intuitive and simple and is carried out via touch screen.

Since autoclaves are electrically heated and consume quite a lot of energy, MK systems can optionally be equipped with an energy recovery system, which saves up to 30% of the electricity costs. This makes the process very stable and reduces the cycle times.